Clean back method

What is Clean Back Method?

The grouting material for the clean-back method consists of milk (Liquid A), which is a special solidification material with stable fluidity for a long period of time, and a clear viscous liquid (Liquid B). In injection work, this liquid A and B is pumped from the ground with a pump and mixed with a special double pipe in front of the grout hole at a ratio of 1:0.08 to 0.10, and the liquid turns into a gel in a few seconds. become The plastic gel remains in a plastic state for 15 to 60 minutes, and by continuously injecting it with pump pressure, it fills the tail voids without being diluted by groundwater. After that, the gel quickly develops strength, reaching a strength of 0.02 to 0.3 N/mm2 in 1 to 3 hours, and quickly stabilizes the ground.

Features

- It has plastic properties and can be injected at the same time as excavation

. The clean-back injection material is a plastic gel that is gelled by the solidifying agent and the hardening agent after mixing the A and B liquids, and is resistant to water dilution. It can be injected for a certain period of time (within the plasticity retention time) because it has the characteristic of becoming fluid when pump pressure is applied and becoming solidified when stationary. Ideal for filling tail voids in shields where there is a lot of water and only a limited injection area needs to be completely filled. - Develops early strength and stabilizes the ground early

Clean-back injection material develops strength equivalent to the ground early after being injected into the tail void. It is possible to respond to various situations by adjusting the necessary strength according to the ground and construction conditions. - It has a low hydraulic conductivity and is excellent in stopping

water.Cleanback grouting material has a low hydraulic conductivity compared to backfill materials that have been widely used, and is excellent in stopping groundwater from entering the shield. - Stable long-term strength

The clean-back injection material maintains stable strength over a long period of time due to the effect of a special hardening material. - Liquid A can be stored for a long period of time

Clean-back injection material A liquid does not harden for 5 to 7 days while maintaining moderate fluidity due to the effects of stabilizers and auxiliary materials. - Long-distance pumping with a pump is possible.

Liquid A, which is the clean-back injection material, is in the form of a slurry, but there is little separation or sedimentation of the material, and good fluidity for pumping can be maintained for a long time. Liquid B is also a low-viscosity liquid, and both materials have characteristics that require pumping over long distances.

Overall flow chart

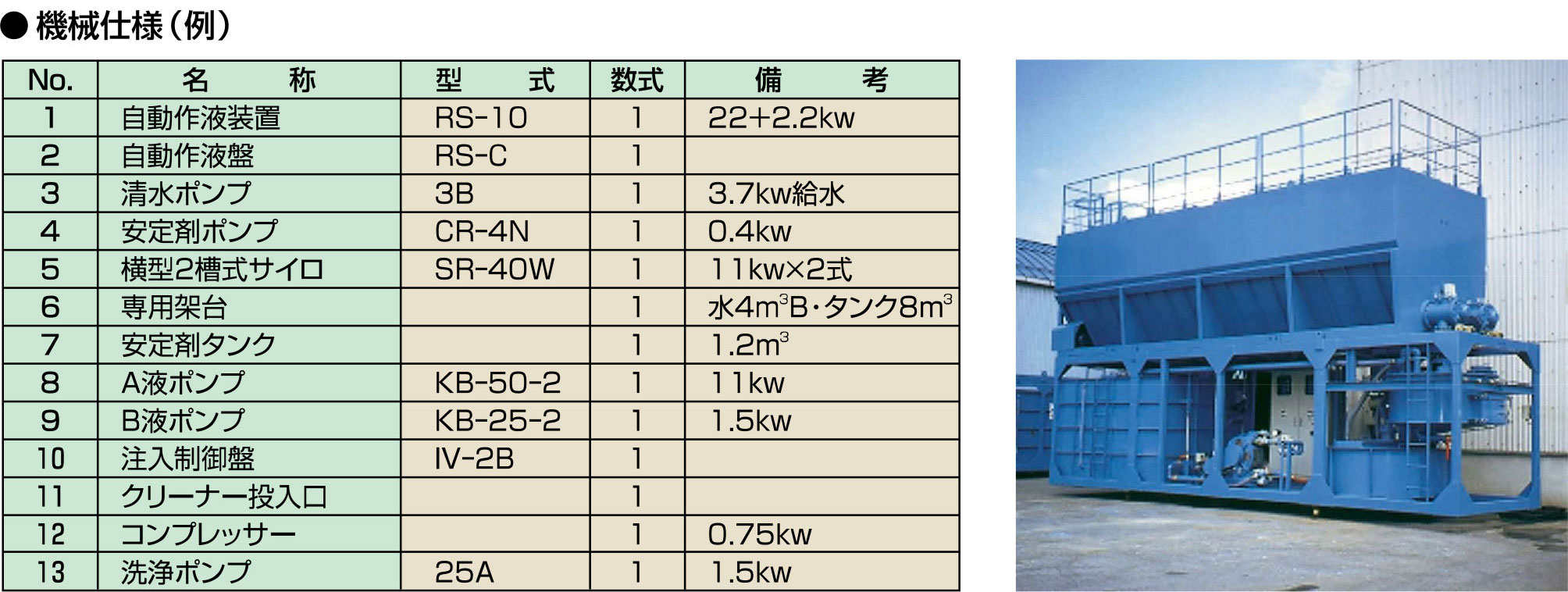

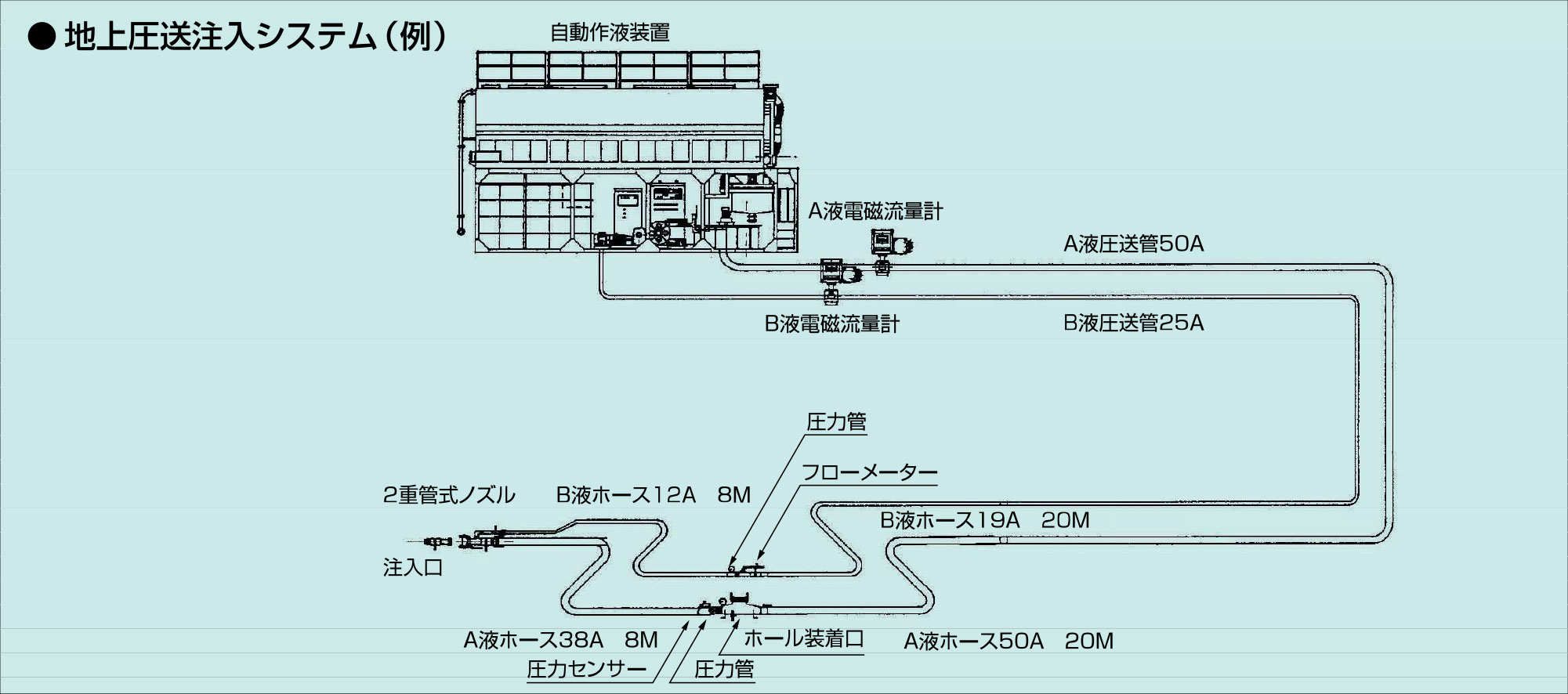

Fully automatic hydraulic plant

The fully automatic liquid plant is equipped with a 18㎥ 2-tank silo in the upper part, and a mixer, agitator and automatic control panel in the lower unit, a water tank, a stabilizer, a hardening agent tank, water and a stabilizer. This is a liquid plant system with a built-in chemical pump. In addition, this unit is equipped with an injection pump for liquids A and B and a control panel in the lower unit.